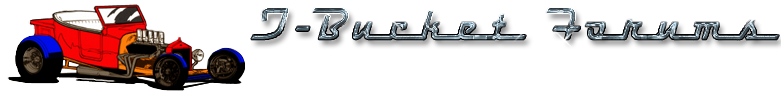

More sanding and Bondo, will it never end? Cut the firewall (inside view) to clear the raised tranny and shaped a slot for all the hoses and wiring from the engine:

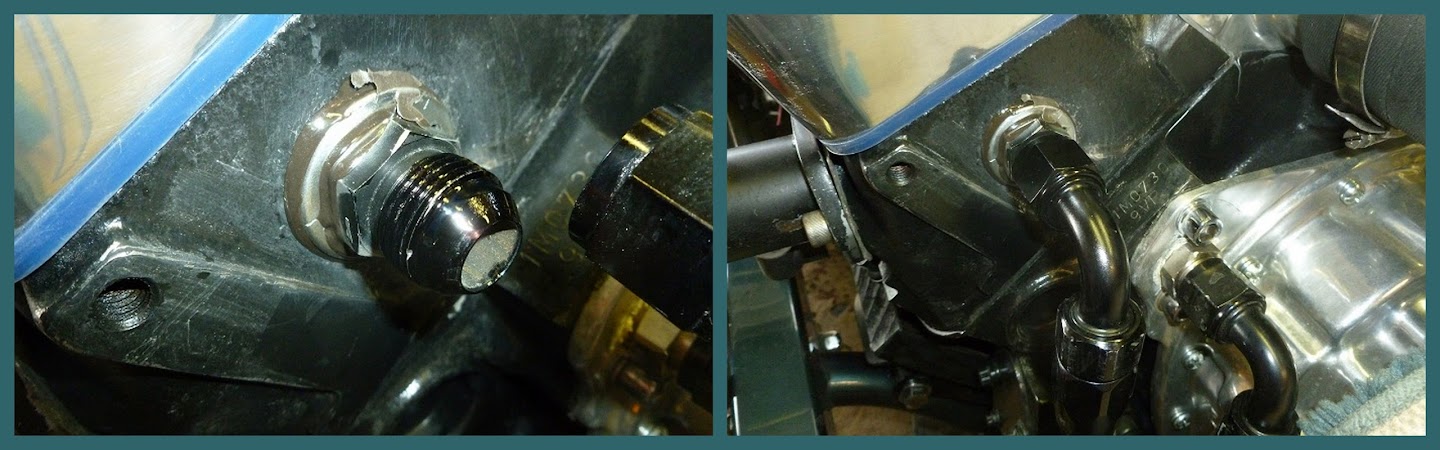

I think I've tamed the Haltech ECU. Added a DC-DC converter to provide the ECU a constant 13 volts regardless of what the alt/battery is putting out. And a readout to check the voltages:

I think I've tamed the Haltech ECU. Added a DC-DC converter to provide the ECU a constant 13 volts regardless of what the alt/battery is putting out. And a readout to check the voltages: